Prior to the invention of floral foam, florists used chicken wire and newspaper, clay or cedar greens as a base for floral arrangements. Discover the fascinating history behind the early days of producing and introducing OASIS® Floral products by selecting any of the links shown below.

Vernon Lewis (V.L.) Smithers (1890-1973)

1985 LTK (Leland T. Kintzele) Distinguished Service Award Presented Posthumously to Vernon Lewis (V.L.) Smithers

Vernon Lewis (V.L.) Smithers was born on July 22, 1890. His career, and eventual path to the floral industry, began in the 1930's, when he was the owner and operator of V.L. Smithers Laboratories, an independent testing laboratory for the tire and battery industries in Akron, Ohio. Sometime after this beginning, V.L. realized the strong desire to be a manufacturer – to make something and sell it!

Smithers' exposure to foam products occurred in the early 1950's when his laboratory was doing work for the Union Carbide Company. Neither Carbide, nor another firm, who subsequently purchased the molds and equipment, were able to find a suitable use for the light-weight, crushable foam. Seeing this challenge as an opportunity, Smithers purchased the equipment determined to find a use for the large blocks of foam it produced.

The start of a new business endeavor was born of pure coincidence. Smithers happened to be glancing at a floral arrangement he had given his wife, and thought, "If I could find a way to get water into foam, perhaps it would be used as a base for floral arrangements." Eureka! – OASIS® floral foam emerged. Following the manufacturing of the product in his laboratory, Smithers established the first production facility in Kent, Ohio in 1953.

Those who knew him stress that Mr. Smithers was not a flamboyant person; he did not want to be in the limelight. He was, rather, a great believer in the industry's organizations and their activities, working hard to ensure that they had his company and its employees' support. Smithers was respected for his concern for others and his natural friendliness.

His industry involvement included membership in SAF, Teleflora, FTD, and of course, WF&FSA. Active in community affairs as well, Smithers was a member of the Masonic Order, Knights Templer, Rotary Club and the Methodist Church.

(L-R) Sons: Robert, William, (V.L. seated), Theodore He spent a total of 20 years dedicated to the advancement of the floral industry. Smithers was a great believer in the investment of his own time in its organization and people. The company continues to be one of the largest supporters of the people and associations which make the floral industry what it is today; a philosophy handed down by V.L. Smithers and his successors, which stressed the value of returning the same kind of support which has made the industry and companies that serve it successful.

Although the products sold by Smithers-Oasis have changed considerably since the 1950's, V.L. Smithers has bequeathed a legacy of undaunted spirit and integrity to both his own company and to the entire floral industry.

V.L. Smithers was still Chairman of the Board when he died at the age of 83.

A pilot plant was first set up in Akron, Ohio. The V.L. Smithers Manufacturing Company was subsequently founded in Kent, Ohio in 1954 to manufacture and distribute OASIS® Floral Foam, a water-absorbing material invented by Mr. V.L. Smithers. Kent was selected as the site of the company because of its proximity to truck transportation lines, emanating from Akron, a scant 11 miles away.

Floral Foam Block Being Scaled by Hand, Circa 1960 Hand Packing Floral Foam Bricks into Cartons, Circa 1962

Original Smithers-Oasis Denmark Manufacturing Facility, Circa 1963 OASIS® Floral Foam Filler "Stix"

OASIS® Floral Foam #5 O'BOWL® Container The early block process of manufacturing, shown here, produced a block which was initially scaled by hand. After shaving the paper, the foam block was then "slabbed" and bricked, then sprayed with a wetting agent to aid absorption and finally packaged.

The company rapidly developed its facilities at the Kent site. Part of the Tru-Car Corporate building was rented from E.L. "Lefty" Miller and later purchased outright. Smithers then purchased a nearby Quonset hut and by 1957, the company had constructed a building to connect the two.

A year later, an office building was added. The following year, the B-Z machine shop was leased. The original plant, an old wood-floored building, was almost completely destroyed in 1961 by fire. Only the office, foaming room and newly built shipping docks were saved. The devastating fire, apparently caused by defective wiring, destroyed much of the specially designed production equipment and consumed much of the supply of finished material.

Following the establishment of a plant in Canada in 1962, our company's first plant outside North America was established in 1963 in Denmark, by Mr. Ib Ingsholt. Ingsholt was a third-generation Danish florist in his prime, twice President for Interflora Denmark, long-standing board member of "Fleurop," and deeply involved in the Scandinavian florist organizations. It was early in August 1960 when Mr. Ingsholt arrived in Detroit, Michigan to participate in FTD's 50-year anniversary convention, little knowing that this trip was going to change his life forever. Ingsholt was invited to demonstrate and show European floristry at the FTD convention. Right there on stage, he met his destiny . . . OASIS® Floral Foam. Never mind the demonstration or competition. The important thing was that Ib Ingsholt, right then and there, ordered his first modest few cases of OASIS® Floral Foam to be shipped to Copenhagen, Denmark for use in his own two shops.

After several shipments, some wholesalers took a little interest and the cartons were now opened upon arrival, checked for transport damage – brick by brick – with the good bricks packed again to be distributed through wholesalers, and "imperfect" bricks saved for use in Ingsholt's own shops. Things developed fast and, as European agent with international connections, the first frail sign of export potential soon became apparent. In 1963, V.L. Smithers Denmark A/S was established and local European production of OASIS® Floral Foam became a reality.

After the introduction of OASIS® "Standard" floral foam bricks, other by-products, foam densities and shapes quickly followed. In 1957, OASIS® Filler Stix, small stick-formed pieces, was one of the first by-products. Used to fill out arrangements in containers, the Filler Stix became a florist staple, which is still found in florist shops today; along with the #5 O'Bowl Container, a plastic utility container still being sold in the U.S. today, designed to hold the #5 OASIS® Floral Foam Cylinder.

If you were a florist in 1954, your design work was likely supported by chicken wire, cedar greens or newspaper filler, placed in the bottom of containers. Delivering a floral arrangement was a gamble. The water would "slosh," flowers would move and often only lasted a day or two.

It was in the same year of 1954, that V.L. Smithers produced the first carton of OASIS® Floral Foam. The product was to revolutionize flower designing, providing a fast, efficient and secure means of designing and handling flower arrangements that lasted longer. Those benefits have allowed modern floristry to develop to its current level of sophistication and efficiency.

From the beginning, the foam held the same amount of water it holds today. A nine-inch by four-inch by three-inch block of OASIS® Floral Foam holds two quarts or four pounds of liquid. This represents more than 50 times is own weight!

Today, floral foam bricks are placed in a tub of water, self-saturate in 60 seconds, and continue to wick water to the flower for the life of the arrangement.

In the early 1950's, Mrs. Ethel "Tommy" Bright, the original floral commentator, went on the road, lecturing, judging and promoting on behalf of industry manufacturers and soon became the spokesperson for the new product, OASIS® Floral Foam.

In the days of wires, cables, carbon copies, manual typewriters and hand-written letters, getting floral foam samples into the hands of floral design schools and florist associations was a priority, relying on slow communications and the natural curiosity of floral designers. With little-to-no knowledge of the florist industry, The V.L. Smithers Laboratories began receiving and responding to requests from florist associations around the country. In a 1954 letter from the Smithers-Oasis archives, it was noted that Bill Hixson, AAF, AIFD, PFCI (Hixson's School of Floral Design) was at that time, appearing in florist association meetings and design schools, praising the new floral foam product.

Design shows were springing up across the country, and these shows proved to be fertile ground for the introduction of this new product.

If you were a florist in 1954, your design work was likely supported by chicken wire, cedar greens or newspaper filler, placed in the bottom of containers. Delivering a floral arrangement was a gamble. The water would "slosh," flowers would move and often only lasted a day or two.

It was in the same year of 1954, that V.L. Smithers produced the first carton of OASIS® Floral Foam. The product was to revolutionize flower designing, providing a fast, efficient and secure means of designing and handling flower arrangements that lasted longer. Those benefits have allowed modern floristry to develop to its current level of sophistication and efficiency.

From the beginning, the foam held the same amount of water it holds today. A nine-inch by four-inch by three-inch block of OASIS® Floral Foam holds two quarts or four pounds of liquid. This represents more than 50 times is own weight! The bricks took almost an hour to saturate and were good for up to 5 days, as long as they were kept wet. The florists kept them sealed in plastic, because once dry, the bricks would not re-saturate.

Today, floral foam bricks are placed in a tub of water, self-saturate in 60 seconds, and continue to wick water to the flower for the life of the arrangement.

In the early 1950's, Mrs. Ethel "Tommy" Bright, the original floral commentator, went on the road, lecturing, judging and promoting on behalf of industry manufacturers and soon became the spokesperson for the new product, OASIS® Floral Foam.

In the days of wires, cables, carbon copies, manual typewriters and hand-written letters, getting floral foam samples into the hands of floral design schools and florist associations was a priority, relying on slow communications and the natural curiosity of floral designers. With little-to-no knowledge of the florist industry, The V.L. Smithers Laboratories began receiving and responding to requests from florist associations around the country. In a 1954 letter from the Smithers-Oasis archives, it was noted that Bill Hixson, AAF, AIFD, PFCI (Hixson's School of Floral Design) was at that time, appearing in florist association meetings and design schools, praising the new floral foam product.

Design shows were springing up across the country, and these shows proved to be fertile ground for the introduction of this new product.

During its first three years on the market, OASIS® Floral Foam was used almost exclusively by florists in preparing arrangements for resale.

Then, unsolicited editorial mentions of the revolutionary new foam material, in brick form, began popping up in flower arranging feature stories in such publications as Good Housekeeping, Better Homes & Gardens, House & Home, House Beautiful, Living for Young Homemakers, American Home and Flower Grower.

Avid home flower arrangers, yes perfectionists, began purchasing OASIS® Floral Foam bricks from their local florists.

It then appeared that an entire new untapped market – home flower arrangers – was opening up. The Smithers-Oasis Division of The V.L. Smithers Manufacturing Company was thus organized to go after this market late in 1960.

The product wasn't launched overnight, but only after a thorough study of the market potential. It was decided that OASIS® Floral Foam should be marketed in convenient 3" diameter cylinders for home use.

These cylinders were packaged in a hexagonal package, which won a first-place award in 1961 from the Folding Paper Box Association of America. The handsome, three-color container, along with other point of sale displays, was designed by The Smith, Scherr & McDermott Co. of Akron.

OASIS® Grower Products represent a second business segment within the field of horticulture for Smithers-Oasis. In 1969, the company introduced its first growing media, Rooting Blocks, for the commercial greenhouse grower market. The growing media offered commercial growers a more stable pH, higher yield and uniform growth rate for plants.

With the initial introduction of the OASIS® ROOTCUBES® growing medium in the early 1970's, Smithers-Oasis revolutionized the vegetative plant propagation industry to where it is today. OASIS® ROOTCUBES®, HORTICUBES®, and WEDGE® growing media products benefit the commercial grower as they are rigid, open-celled, water-absorbing foams, specifically engineered for optimal callus and root formation. Crops most commonly rooted in OASIS® media are poinsettias, geraniums, spring flowering crops, foliage, hibiscus, herbs, lettuce, and woody ornamentals. The performance of these media is due, in part, to the unique cell structure that closely resembles the cellular structure of the plant itself. The composition of the foams gives density (weight) for holding power and capillary action for delivering water to inserted plant cuttings.

In 2006, Smithers-Oasis acquired the FERTISS® Propagating Plug System in North and South America from Fertil S.A.S of France. FERTISS®, a soilless rooting plug, provides easy rooting and seeding of most plant types. The rooting plugs are composed of a special blend of long fiber sphagnum peat, perlite and vermiculite, wrapped in a cellulose non-woven net. Roots easily penetrate the wrapping and are naturally air pruned, resulting in a faster and better take. The product will be sold under the registered name, OASIS® FERTISS® Growing Medium, and manufactured at the company's Kent, Ohio facility. The FERTISS® Propagating Plug System provides the company the final key for its good-better-best product offering.

Today, OASIS® Grower Products offer a wide variety of rooting systems that are adaptable to nearly every type of plant. These offerings help us to serve a wide variety of growers, from small-scale operations which rely on superior survival rates, to mass retail growers, who require an excellent product at a competitive price.

The very first Floralife® fresh cut-flower food was produced and sold back in 1938. Its beginning was a joint venture between a successful commercial grower of roses, William Bussert, and a Chicago cut-flower wholesaler, James Sykora, Sr. of the Amling Co. The initial packaging of the powder product was a capsule format in which the customer opened, added and stirred into water. The directions required the customer to add ordinary table sugar to the mixture. Due to the short supply and rationing of sugar during World War II, sales quickly lagged.

In 1944 Floralife® flower food was reintroduced and the Floralife company formed. Early advertising for Floralife® products featured 20th Century Fox star actress, Joan Bennett. With promotional success, additional floral innovations soon followed, such as FloraDye™ (flower dye), FloraWax™ (prevented set-piece wilt), FloraKwick-Stick™ (a quick floral cement) and FloraGlow™ (makes potted plants "Glow and Grow").

Floralife, Inc. generated a full line of high-end designer floral sprays to appeal to ever-changing consumer demands in the 1960's. Mist 'n Dye™, gave florists the ease of dyeing just one or two flowers at a time.

In the 1980's, "Dew-y" became Floralife's cartoonish character promoting flower quality and providing FloraCare information through a comprehensive care and handling manual. The introduction of FloraCare products included Silflor®, Hydraflor®, D.C.D.® and a flower food for different water types, Special Blend Pure and Special Blend Hard.

Country colors were the rage in home décor and Floralife answered the demand with the Homestead Color Collection. Floralife® Hot Melt GluGuns® and GluStiks® gave florists more flexibility in designing.

In the 1990's, with the acceptance of the worldwide web, Floralife, Inc. launched www.floralife.com, an internet tool that would aid in the marketing and education of Floralife® products. Floralife, Inc. introduced EthylBloc™ Technology, the first patented government-approved ethylene action inhibitor to the floral industry. This was a monumental step to eliminating leaf yellowing, flower wilting, and significantly increasing flower life.

Floralife's selection of flower food products expanded to offer "holding solutions," such as Floralife Professional® and Clear Professional® liquids, to mass markets and wholesalers for fresh flower storage.

In 2000 and beyond, Floralife, Inc. launched crop-specific Bulb and Rose flower foods, along with the first scented fresh flower food, Floroma®. Followed by this came eZ Dose® Flower Food, a fast-dissolving, easy-to-use holding or shipping solution for the bouquet and retail market.

In 2006, Floralife, Inc., a privately held company up to this point, was sold to Rohm & Hass, the worldwide chemical conglomerate. Shortly thereafter in January 2007, Smithers-Oasis Company, the worldwide leader in floral foam and floral design accessories, acquired the organization. With the synergies of both companies, Floralife, Inc. expanded with worldwide distribution networks throughout North and South America, Asia, India, Europe, Africa, Australia and New Zealand.

Under the “OASIS®” brand name, the foam product was considered revolutionary in providing a fast, efficient and secure means of designing and handling flower arrangements. The subsequent and rapid interest in the product provided for expanded production facilities throughout the world.

It was in 1986 that the Company’s ownership was transferred to Charles F. Walton of The Smithers-Oasis Company. With this transition, the company name was changed to Smithers-Oasis Company. Mr. Walton is currently a member of the Company's Board of Directors. In February of 2011, majority ownership of the company was transferred from Charles Walton to Robin M. Kilbride, President and Chief Executive Officer, and members of senior management.

Today, Smithers-Oasis Company is headquartered in Kent, Ohio. The company’s products are manufactured and distributed by its facilities in Belgium, China, Colombia, France, Germany, India, Malaysia, Mexico, Slovenia, South Korea, Spain, the United States, the United Kingdom, and through third-party licensing arrangements in South Africa and Brazil. Sales offices are also maintained in Australia and Japan. Floralife serves the entire postharvest distribution channel, including growers, bouquet manufacturers, mass marketers, wholesale and retail florists throughout the world.

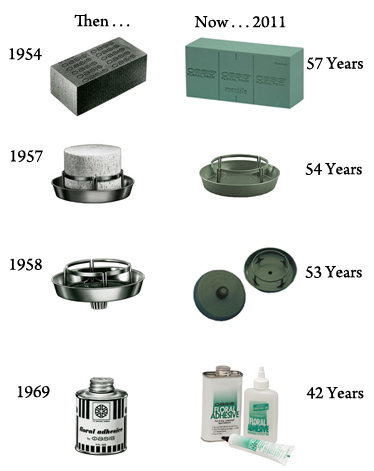

When looking through the Smithers-Oasis archives, a collection of old product photos was discovered. Taking a second glance, the products appeared so familiar… and they should! It is amazing to see how many of our products are still around in their original form and have truly stood the "test of time!"

It was no surprise that the original brick of floral foam, named OASIS® Standard Floral Foam, is still around today. The product name may be different in other countries, but in North America – a brick of OASIS® Standard Floral Foam then, is still a brick of OASIS® Standard Floral Foam today. Invented in 1953 and patented in 1954, this product celebrates 57 years with the company!

The #5 O'Bowl and foam cylinder insert was introduced in 1957 – incredibly 54 years old, it is still a staple in florist shops today.

Launched in 1958, the O'Dapter, created as a design accessory for candle sticks and small-neck containers, was then packaged and sold for $1.00 to the consumer, including the floral foam insert.

Celebrating 42 years young, OASIS® Floral Adhesive may have changed its original "stylish" metal can a little, but the stuff inside still holds true!

With so many years of experience, time-tested products and consistent quality, it is no wonder that florists across the globe depend on OASIS® Floral Products as a staple in their shops. As a consumer, you want a florist who is not only creative, but reliable and professional. Every florist knows that OASIS® Floral Products are the best tools in the industry to provide their customers with the best floral designs!

When it comes to customer satisfaction and longer lasting flowers, Smithers-Oasis has been committed since day one to making sure every brick of floral foam we produce will provide a healthy foundation for long-lasting arrangements.

Today, the black and white photo of the flower test room shown here has been replaced with beautiful colors. The research and technology that backs up every piece of OASIS® Floral Foam will probably never be known by the recipient. However, a lot of talent is put forth by the florist, whose creativity and reputation is on the line with every arrangement and is the driving force behind our motto of "consistent quality."

Our wettable floral foam has a cell composition that permits control of saturation time and provides increased water transfer capabilities. This assures maximum cut-flower life of arrangements made in OASIS® brand Floral Foam.

Because our foam formulations are proprietary, much of the equipment used to produce them has been customized by our in-house engineering staff to meet our specific processing needs. Since product quality is one of our primary driving forces, the technicians in our quality assurance labs continually test both raw materials and finished products to make sure they meet our rigid quality specifications.

A greenhouse, located at our Kent, Ohio manufacturing facility, allows our OASIS® Grower Products to undergo all sort of quality testing to ensure our commercial greenhouse customers receive the quality product they have come to depend on.

All in all, Smithers-Oasis is truly dedicated to producing a quality product, time and time again! As with photography, the world is not black and white, but alive with flowers and foliage of all varieties and colors. Don't risk your reputation on anything less than OASIS® brand Floral Products.

From 16mm sound films, 35mm filmstrips and 33-1/3 rpm records, to black & white brochures (showing flowers no less!), getting the word out to florists about designing with floral foam took many different directions.

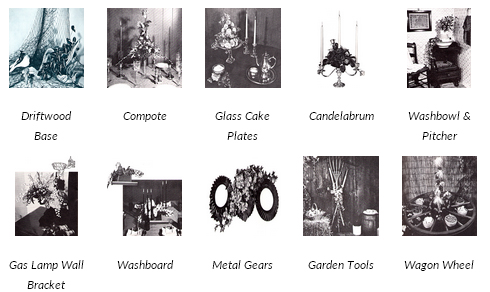

Shown here is a clever idea taken from the 1963 Smithers-Oasis "Adventure with Flowers" brochure, where antique-shop finds were used as containers. Here, two meat grinders were used to create these cute table designs.

Other unusal design container ideas from this brochure included (please excuse the poor quality of the images – black and white pictures of "antiques" – which are even more antique now! – just don't do justice to these clever old-fashioned designs):

The arrangements created in this particular booklet were designed by Bill Hixson, and photographed by Robert Smithers. Two more very influential people in the pages of floral design history!